Doing the farm chores at 5:30 this morning, I portioned out sweet grain for the girls, slid a bowl of grain each for Mac and Murphy under their gate, and topped off the pig feeder with a 50-pound bag. Then, with the lift of a blue handle, I filled a 5-gallon bucket of water. One for the pigs, then another for the boys and another for the girls. It was -1 degree with a breeze, but the water flowed. The liquid miracle brought back memories of a September weekend filled with talcum powder soil dried out by a long summer drought when we redid our entire farm water system to make life easier when temperatures bottom out.

We’ve always had running water across the street for the animals. John Murphy’s old A-Frame had block lined dug well about 12′ deep. I had built a small insulated pump house to put over the top, and hung a heat lamp to keep the pump and pressure tank warm in the winter months. We’d fill buckets from a sillcock on the outside, and carry them to the animals twice a day. Aside from the joys of carrying heavy buckets up an icy slope, through a gate and across the barnyard, the system had other drawbacks as well. The warm pump house attracted rodents looking for a warm winter home. Mice and chipmunks would chew the insulation and leave other less-pleasant signs of there existence before ultimately meeting their fate in the drinking water below. We wouldn’t serve the water to a friend, and weren’t comfortable with it as a long-term solution for the animals either.

So we devised a plan. Around here, plans mean projects— expensive, difficult, time consuming projects that anyone without a farm would hire a professional to do. The goal is to make farm life easier in the longterm, but easier can be quite difficult in the short-term.

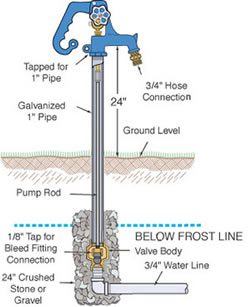

The plan in this case was as follows: move the pump and pressure tank to farm stand, feed it with a waterline coming from the well, then run waterlines from the farm stand to each of the animal areas; one up to the girls barnyard, one to the boys gate, and one outback to the pigs, which we’d be raising in the winter for the first time. All the waterlines had to be 5′ below ground to keep from freezing and connected to frost-free hydrants. Then, we’d do away with the old pump house and cap the dug well with a concrete lid to keep the rodents out.

The known challenges included digging in our boulder filled terrain along with getting the waterlines through the concrete foundation wall and up through the slab floor of the farmstead. Plus the overall scale; hundreds of feet of trench and waterlines, yards of boney soil to remove, tons of clean sand to backfill, truck fulls of drainage stone and 7′ tall hydrants installed 5′ below ground.

I stockpiled raw materials during the week leading up to project, and made multiple trips to the plumbing supply house to make sure we had everything we might need. I bought home an excavator after work on Friday (this is how we spend our weekends) and started to dig that night. By the end of the day Saturday the entire barnyard in every direction was either a 5′ deep trench, a 6′ tall mound of dirt or a pile of unearthed rocks ranging from the size of a basketball, to the size of a large trash barrel.

On Sunday Jeff, George (one person, and two) and Liz slung black poly pipe, and surrounded it gently with clean sand. They hooked up the yard hydrants and bedded them in drainage stone below ground. They tightened hose clamps, connected barb fittings and one of the, fell head first into a 6-foot deep trench. Brian piloted the tractor, spreading old fill this way and that while bringing back clean sand to backfill. Wayne relieved me in the excavator after lunch, and thrashed until the last trench was dug and filled well after dark.

In the following days, as the dust literally settled, I hooked up the pump system and water began to flow from the well, to the farmstead and out to the hydrants. And this morning, with windchills below zero in continued to flow, now clean and clear, straight to the animals. When it comes to the goats and chickens, the project made life easier—the girls drink about five-gallons per day, the boys a bit less. However, it made raising pigs in the winter possible. Even now, at about half the size they will become, the four pigs are going drinking close to 20-gallons per day. Hauling buckets any distance to their waterer wouldn’t have been practical. The project also made it so we could put a sink, and a frost free faucet in the Sugar House to help with cleanup during sugaring season.

The next trick is keeping the water from freezing once its too the animals. I’ll write about those strategies another time.

A few notes: We had some amazing helpers on this project. Some are mentioned above, others know who they are. Thanks to all. There was also a few side projects that happened at the same time: replacing all the below ground electrical wiring I inevitably dug up during the project, installing site drainage to help solve some water issues, and putting in a dry well.